Texas Instruments began working on a spatial light modulating technology nearly twenty-five years ago. Starting as the Deformable Mirror Device in 1977, the technology evolved over the following years, leading to Dr. Larry Hornbeck’s invention of the optical semiconductor known as the Digital Micromirror Device (DMD) chip in 1987. Over the next decade the DMD technology was perfected, and with the necessary support electronics, was commercialised in the form of Digital Light Processing technology in the spring of 1996.

Currently, the DMD chip remains the only volume production device that is both a micro-electronic mechanical system (MEMS) – because it consists of hundreds of thousands of moving micromirrors that are controlled by underlying semiconductor electronics – and a spatial light modulator (SLM).

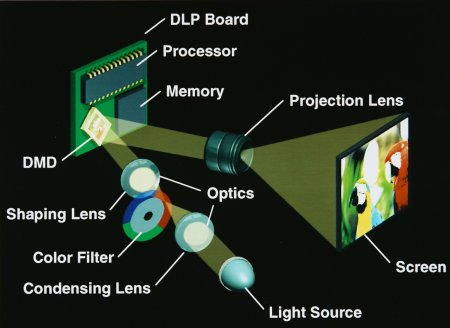

When used in conjunction with a digital video or graphic signal, a light source, and a projection lens, a DMD chip’s mirrors can reflect an all-digital image onto a screen or other surface. This makes it perfect for use in projector applications, and the emergence of DLP-based projectors in the mid-1990s was a catalyst for the development of compact, highly portable digital projectors.

A DMD panel’s micromirrors are mounted on tiny hinges that enable them to tilt either toward the light source (ON) or away from it (OFF), creating either a light or dark pixel respectively on the projection surface. The bit-streamed image code entering the semiconductor directs each mirror to switch on and off up to several thousand times a second. A mirror that’s switched on more frequently than off reflects a light grey pixel; a mirror that’s switched off more frequently reflects a darker grey pixel. In this way, the mirrors in a DLP projection system can reflect pixels in up to 1,024 shades of grey to convert the video or graphic signal entering the DMD into a highly detailed greyscale image.

The white light generated by the lamp in a DLP projection system passes through a colour wheel as it travels to the surface of the DMD panel. The colour wheel filters the light into red, green, and blue, from which a single-chip DLP projection system can create at least 16.7 million colours.

The on and off states of each micromirror are co-ordinated with these three basic building blocks of colour. For example, a mirror responsible for projecting a purple pixel will only reflect red and blue light to the projection surface; the human eye then blends these rapidly alternating flashes to see the intended hue in a projected image.

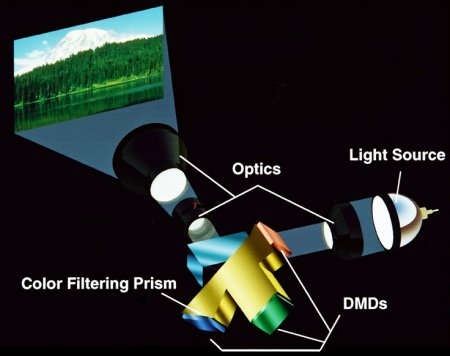

High-end DLP projectors – such as those used for cinema projection or other large venue displays – use a 3-chip configuration – thereby obviating the need for a colour wheel – to produce stunning images with no fewer than 35 trillion colours.

The principal advantage of DLP projectors is their smaller size. Since DLP technology requires no colour-combining prisms or complex separation optics, its optical system is more compact than transmissive LCD systems. Also, DLP chips don’t require as much cooling as LCD projectors, since they aren’t affected by extreme heat as much as LCD filters and panels.

Another advantage of DLP is that they suffer less from the screen door effect than the rival LCD technology because their control circuitry isn’t as large. However, some models do suffer with what’s known as the rainbow effect.

The latter is an artefact unique to single-chip DLP projectors and was particularly prevalent with first generation of DLP projectors which used a 4-segment colour wheel – comprising Red/Green/Blue and usually a clear segment – rotating at 3,600 RPM. Some people observe this artefact – which appears as a momentary multicolour shimmer – in their peripheral vision as they change focus from one part of the projector screen to another, especially when shifting focus from a high contrast area or bright object.

The problem is a consequence of the fact that with DLP projectors, not all the colours in an image are projected at the same time. 6-segment colour wheels are less badly affected. These typically spin faster and are made up of 2 sets of Red/Green/Blue segments, thus enabling a faster colour-refresh rate. Texas Instruments’ HD2+ chip design incorporates an additional colour (dark green) into a 7-segment colour wheel, enabling better colour reproduction and contrast ratios greater than 3000:1.

DLP technology has undergone a number of other improvements since its introduction in 1996:

- In the late 1990s, the mirror pitch was reduced from 17um to 13.7um, allowing smaller device footprints and reduced cost.

- In 2000, the data load rate was increased from single data rate (SDR) to double data rate (DDR), enabling more accurate greyscale reproduction.

- In 2002, mirror tilt was increased from +/- 10 degrees to +/-12 degrees, enabling increased optical efficiency.

DLP technology really came into its own for home theatre use with TI’s announcement, in the summer of 2001, of the first DMD chip the company had developed specifically for front projection video applications. Its HD1 chip had previously featured in rear projection home entertainment systems. The version optimised for front projection applications featured an array of 1,280 x 720 pixels, allowing it to deliver both native support for 720p as well as 16:9 aspect ratio, giving it true HD capability. DLP projectors based the new chip proved significantly better than earlier designs, particularly in the depth of their blacks.

The subsequent HD2 chip has the same resolution as the HD1, but rotates 12° to the off position instead of the HD1’s 10° tilt. By directing light from the projector’s bulb farther away from the lens, allowing more of it to be absorbed, this enables the production of even deeper blacks.

The most recent development has seen the contrast ratios improved from 800:1 to >1500:1 by the application of a light-eating dark metal coat to the interior of each chip, preventing stray light from travelling to screen when mirrors are switched off.

Further improvements are on the horizon. For example, TI are working on a new technology that has been mathematically projected to rival the current quality of 3-modulator DLP Cinema systems in a single modulator device. Referred to as Sequential Colour Recapture (SCR), this will see the replacement of the traditional multi-segment colour wheel with an SCR wheel, created from RGB dichroic coatings arranged in a Spiral of Archimedes pattern.