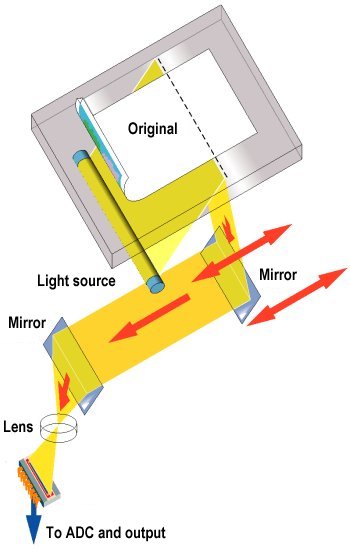

On the simplest level, a scanner is a device which converts light (which we see when we look at something) into 0s and 1s (a computer-readable format). In other word, scanners convert analogue data into digital data and can have a Document Data Capture.

All scanners work on the same principle of reflectance or transmission. The image is placed before the carriage, consisting of a light source and sensor; in the case of a digital camera, the light source could be the sun or artificial lights. When desktop scanners were first introduced, many manufacturers used fluorescent bulbs as light sources. While good enough for many purposes, fluorescent bulbs have two distinct weaknesses: they rarely emit consistent white light for long, and while they’re on they emit heat which can distort the other optical components. For these reasons, most manufacturers have moved to cold-cathode bulbs. These differ from standard fluorescent bulbs in that they have no filament. They therefore operate at much lower temperatures and, as a consequence, are more reliable. Standard fluorescent bulbs are now found primarily on low-cost units and older models.

By late 2000, Xenon bulbs had emerged as an alternative light source. Xenon produces a very stable, full-spectrum light source that’s both long lasting and quick to initiate. However, xenon light sources do consume power at a higher rate than cold cathode tubes.

To direct light from the bulb to the sensors that read light values, CCD scanners use prisms, lenses, and other optical components. Like eyeglasses and magnifying glasses, these items can vary quite a bit in quality. A high-quality scanner will use high-quality glass optics that are colour-corrected and coated for minimum diffusion. Lower-end models will typically skimp in this area, using plastic components to reduce costs.

The amount of light reflected by or transmitted through the image and picked up by the sensor, is then converted to a voltage proportional to the light intensity – the brighter the part of the image, the more light is reflected or transmitted, resulting in a higher voltage. This analogue-to-digital conversion (ADC) is a sensitive process, and one that is susceptible to electrical interference and noise in the system. In order to protect against image degradation, the best scanners on the market today use an electrically isolated analogue-to-digital converter that processes data away from the main circuitry of the scanner. However, this introduces additional costs to the manufacturing process, so many low-end models include integrated analogue-to-digital converters that are built into the scanner’s primary circuit board.

The sensor component itself is implemented using one of three different types of technology:

- PMT (photomultiplier tube), a technology inherited from the drum scanners of yesteryear

- CCD (charge-coupled device), the type of sensor used in desktop scanners

- CIS (contact image sensor), a newer technology which integrates scanning functions into fewer components, allowing scanners to be more compact in size.

What is the date of this article?

not bad