In perpendicular recording, the magnetisation of the bit is aligned vertically – or perpendicularly – in relation to the disk drive’s platter. Since the bits do not directly oppose each other, the need for transition packing is significantly reduced. This allows bits to be more closely packed with sharper transition signals, facilitating easier bit detection and error correction. The potential for higher areal density results.

To help understand how perpendicular recording works, consider the bits as small bar magnets. In conventional longitudinal recording, the magnets representing the bits are lined up end-to-end along circular tracks in the plane of the disk. If you consider the highest-density bit pattern of alternating ones and zeros, then the adjacent magnets end up head-to-head (north-pole to north pole) and tail-to-tail (south-pole to south-pole). In this scenario, they want to repel each other, making them unstable against thermal fluctuations. In perpendicular recording, the tiny magnets are standing up and down. Adjacent alternating bits stand with north pole next to south pole; thus, they want to attract each other and are more stable and can be packed more closely.

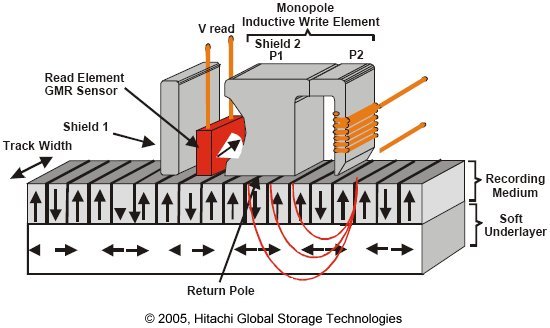

Key to being able to make the bits smaller, without superparamagnetism causing them to lose their memory, is the use of a magnetically stronger (higher coercivity) material as the storage medium. This is possible due to the fact that in a perpendicular arrangement the magnetic flux is guided through a magnetically soft (and relatively thick) underlayer underneath the hard magnetic media films (considerably complicating and thickening the total disk structure). This magnetically soft underlayer can be effectively considered a part of the write head, making the write head more efficient, thus making it possible to produce a stronger write field gradient with essentially the same head materials as for longitudinal heads, and therefore allowing for the use of the higher coercivity – and therefore inherently more thermally stable – magnetic storage medium.

By 2005 all of the major hard disk manufacturers were working on PMR technology and the technology was expected to be broadly adopted in products by the end of 2007. Hitachi Global Storage Technologies demonstrated an areal density of 345 Gbits/in2 in laboratory testing in the autumn of that year, expected to bring hard drive areal density half way to the 345 Gbits/in2 mark with a 1 TB 3.5in product in the first half of 2007, and was predicting a 2 TB 3.5in desktop drive by 2009.

Extensions to PMR technology are expected to take hard drive advancements out beyond the next two decades, and eventually allow information densities of up to 100 Tbits/in2

- Hard disk (hard drive) construction

- Hard Disk (hard drive) Operation

- Hard disk (hard drive) format – the tracks and sectors of the hard disk

- File systems (FAT, FAT8, FAT16, FAT32 and NTFS) explained

- Hard Disk (Hard Drive) Performance – transfer rates, latency and seek times

- Hard Disk AV Capability

- Hard Disk Capacity

- Hard Disk Capacity Barriers

- Hard Disk MR Technology

- Hard Disk GMR Technology

- Hard Disk Pixie Dust

- Hard Disk Longitudinal Recording

- Hard Disk Perpendicular Recording

- RAID – Redundant Arrays of Inexpensive Disks

- Hard Disk SMART Drives

- Hard Disk MicroDrives

- Hard Disk OAW Technology

- Hard Disk PLEDM

- Hard Disk Millipede

- Guide to Western Digital’s GreenPower hard drive technology

- Solid state hard drive (SSD) technology guide